Recent searches

Search options

Hey! Once again it's #FreeCADFriday! Show us what you are working on in #FreeCAD.

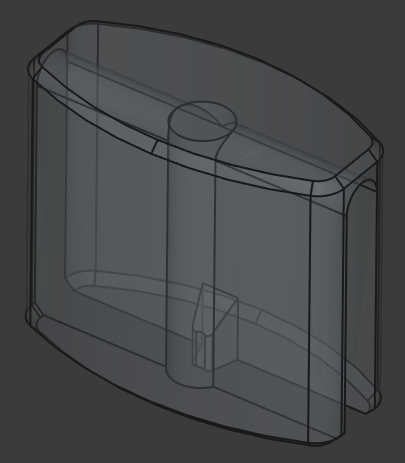

@M4x I might go to a simple screw driven cylinder pump, I'm sure I can get some food safe leadscrews/nuts

@M4x doing some back of the napkin (or rather python repl as a calculator) math I'd generate about 3MPa (with a normal nema17 stepper) of pressure with the cylinder pump, and that *should* be *about* adequate. Otherwise I could reduce the cylinder area, or use a bigger motor.

@FreeCAD On todays #FreeCADFriday I've added a "tilt support" to my rear lighting bracket for the basket of a kids bicycle. The first iteration worked quiet well but it's tilting a bit and the strap wasn't as tight as I wanted it to be (yes, #1stworldproblem ). While I'm writing this, I realize that I still haven't posted a picture of the 3D-printed part of the first iteration

@FreeCAD I've printed the design today. It worked flawlessly without support. Yes, the detailed contact area of the tilt support might be over-engineered for a FDM printer with a 0.4 mm nozzle. But isn't there a saying? You can never be overdressed or over-engineered (or something like that). However, it fits great. I'm going to add a rubber strip between the printed part and the light but otherwise, that's it (apart from publishing the model -> 2do list )

#FreeCAD #fc3d #3dprinting #bicycle